UPM-Kymmene Otepää AS is one of the fifteen partners in the Woodworking Industry Development Cluster and is part of the international UPM Corporation, with head office situated in Helsinki, Finland. With manufacturing sustainable and innovative products in 12 different countries, UPM leads the integration of bio and forest industries into a new, innovation-driven future. For UPM, this is captured in one word – Biofore. It means versatile use of recyclable and renewable wood biomass, combined with innovation, efficiency and responsibility. UPM has 8 plywood mills (6 in Finland, 1 in Russia, 1 in Estonia) and 1 veneer mill in Finland, which together make UPM Plywood. UPM Plywood`s vision is to be the most wanted supplier-partner for the leading industrial plywood users and distributors. Mission is to create value to company`s customers by supplying high quality products and services efficiently and punctually, to renew and improve operations continuously.

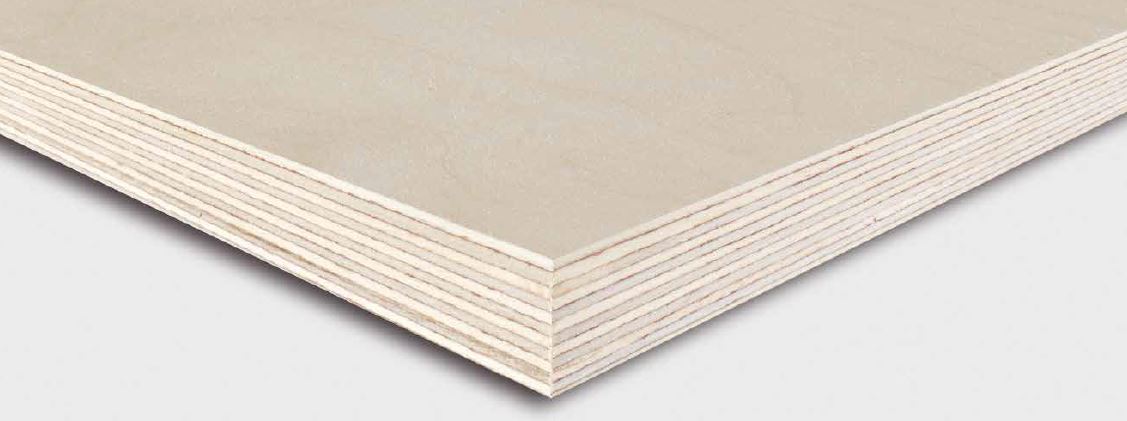

UPM-Kymmene Otepää AS is located in southern part of Estonia and is producing birch veneer and plywood products. Company is manufacturing uncoated and coated WISA® birch plywood of multiple variety for different demanding end-uses worldwide. Products are made from birch logs from forests managed according to the principles of sustainable forestry. UPM Otepää mill is certified to ISO 9001 and ISO 14001 standards and has a license to use CE marking on its products. Usage of birch plywood panels is practically limitless. Different types of WISA® coated plywood panels are designed to be used in applications such as the sub floor of the buses and coaches, flooring elements of the heavy transport trailers and light transport trailers, building applications, loading platforms and scaffolding, delivery vans, stages, sports hall applications etc. Special type of coated WISA® plywood can be used for concrete formworking. WISA®-FiRe is a birch plywood panel with improved fire safety properties integrated into its coating, which is primarily intended to be used in passenger transportation, coaches, buses and trains, where high standards are set for fire safety. WISA®-Phon N is a birch plywood sandwich panel with good sound-absorbing properties due to rubber layer between veneer plies. It is mainly intended for use in the transportation industry (bus and train floors, engine rooms etc.) where sound-absorbing features are needed. WISA®-Birch uncoated plywood panels are meant for multiple end-uses, e.g. in construction, furniture and LNG carriers.

At any given time, there are more than 370 carriers at sea transporting liquefied natural gas (LNG). More than half of these feature insulation elements made of birch plywood supplied by UPM and produced under strict quality control. When natural gas is to be transported over long distances, it must first be liquefied by cooling the gas to –163°C. The low temperature means that the LNG must be transported on special purpose tankers which have excellent heat insulation. Storage tanks insulation elements combine of different materials including birch plywood, which is a prime structural material for this demanding use. Insulation elements are built around the tanks, a double insulation layer for each tank. Birch plywood is relatively light but durable, and there are only few materials that can be compared when it comes to its weight to strength ratio. Birch plywood maintain its dimensions and strength even at very low temperatures. South Korea is the most important builder of LNG carriers in the world, and UPM has been supplying plywood to the local shipbuilders since the late 1960s. Builders of LNG carriers both in South Korea and China use UPM’s WISA®-LNG plywood made in Otepää mill.

UPM Corporation and UPM Plywood is always on the lookout for new solutions for their client needs. Together with their partners they are building a sustainable future based on versatile use of renewable wood biomass.

For more information about producing process of veneer and plywood, read more here !

WISA®-Phon N is a birch plywood sandwich panel with good sound-absorbing properties

Stacked semi-finished plywood in UPM Otepää production unit. For additional safety, UPM forklifts are equipped with blue-colored warning lights as seen in the photograph

Variations of WISA® plywood from UPM

The LNG carrier storage tank, where plywood supplied by UPM is used

Schematic view of the insulation of LNG carrier storage tank